Limited Modifications, Limitless Opportunities

✓ Profitable

Offer your customers premium functionality without premium costs.

✓ Scalable

Flexible for low and high-volume production capacities

✓ Compatible

Designed to integrate with existing manufacturing equipment and supply chain logistics

CanReseal The Resealable Can That Works with Your Existing Lines

Leverage CanReseal’s compatibility, scalability, and profitability to fuel your business growth without the need for disruptive overhauls at either the manufacturing or filling stages.

Built for Compatibility,

Designed for Growth

Future-Proof Your Operations Without Disruption

CanReseal is engineered to integrate with current can manufacturing and filling, minimizing machinery and operational changes while maximizing efficiency.

"We have partnered with Canovation due to their revolutionary and fully sustainable CanReseal technology that will usher in a new era of consumer packaging."

Ian Scholey, Chief Technical Officer | Stolle Machinery

Don’t Miss Out on the Consumer Led Packaging Revolution

Adapt. Evolve. Lead.

The rapid shift away from single-use plastics presents a massive growth opportunity for aluminum packaging. CanReseal meets this demand head-on, allowing manufacturers and fillers to capitalize on market trends without costly investments.

✓ Minimal Change, Maximum Impact

CanReseal fits within existing supply chain logistics.

✓ Future-Ready

Designed to meet consumers’ growing sustainability demands while boosting profitability & product appeal.

✓ Maintain Supply

Maintain and use the supply of your current local cans, as CanReseal can be seamed onto 100% of all standard beverage and food cans with no changes to your can bodies.

Flexible Integration

Expand your manufacturing capabilities without sacrificing efficiency or cost-effectiveness.

We understand your hesitation to adopt new technologies. That’s why we’ve designed CanReseal with flexibility in mind. Start with incremental steps and gradually evolve your lines as your consumer demand grows!

While we finalize our development, you can request a sample today to begin validating CanReseal’s performance, test consumer reception, and explore integration opportunities!

Increase Market share

Closures with different functionalities mean you can increase your sales by entering new markets, beyond traditional canned beverages and food!

Check out our brands page for more information!

Improve Your Top Line

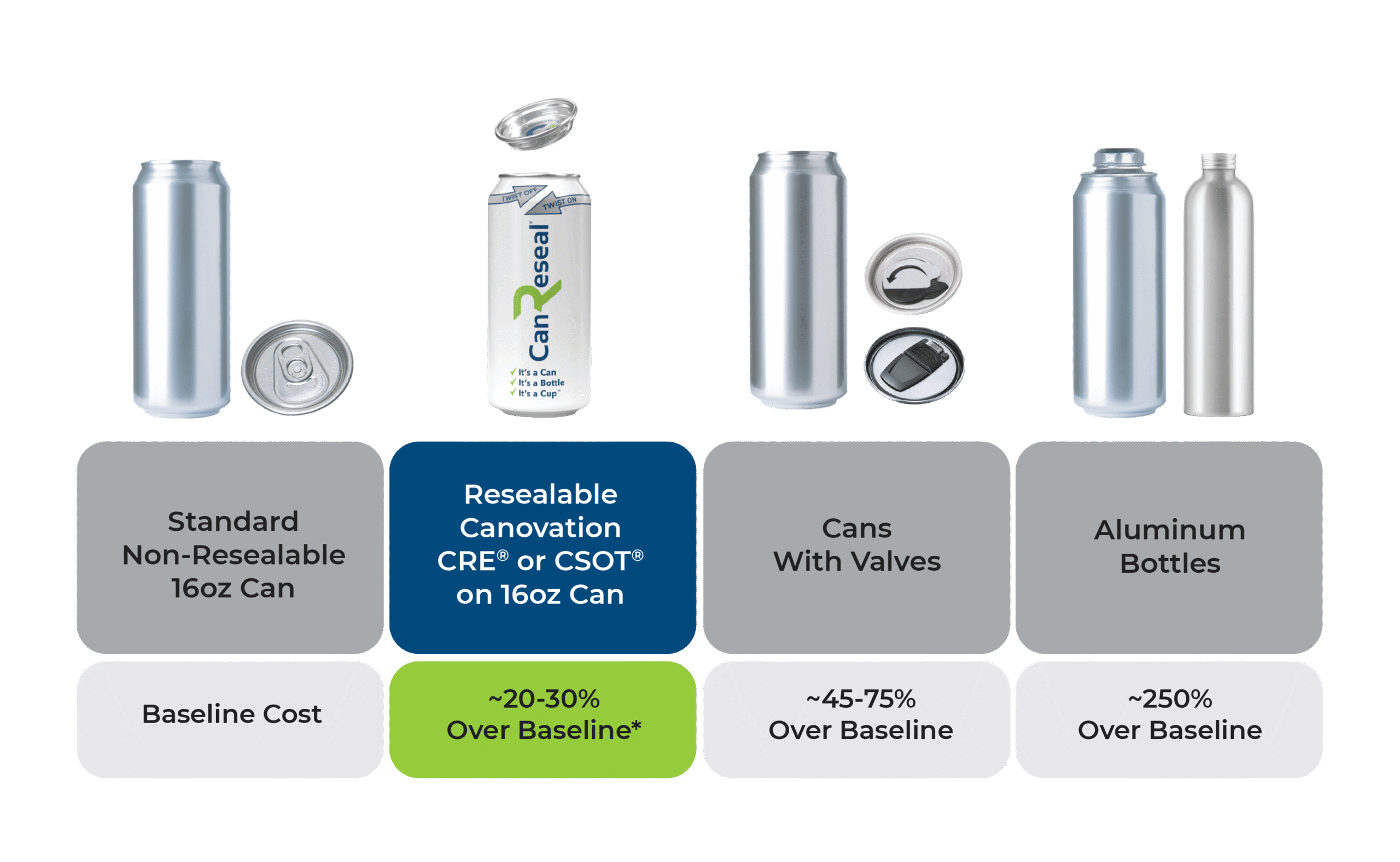

● Our estimates show CanReseal costs are comparable to traditional ends!

● CanReseal Ring Ends (CRE) and closures are made the same way ends are made today!

● The cost of CanReseal is simply just the cost of two ends!

● This slight cost increase is negligible to both brands and their end consumers

FAQs

Send us your questions!

CanReseal® is targeted to be a low-cost alternative to single-use plastics and aluminum bottles. With the additional material usage, we anticipate a 20-30% markup from traditional non-resealable cans, which is still far more affordable than aluminum bottles. An easy way to look at our cost model is to assume that you are simply purchasing two can ends (our ring end and closure).

a. We anticipate our pilot line to begin production in the summer of 2026. From this low-volume production line, we are targeting ≥10M CanReseal® cans annually for brands to initiate controlled consumer test markets.

b. Full commercialization of CanReseal is expected 12-18 months following the initiation of our pilot line. We estimate upwards of ≥2B CanReseal® cans to be produced annually from a fully automated commercial line.

a. Can Bodies - potentially nothing will be required to change with the production and supply of can bodies. Depending upon fill

heights, there may be some slight adjustments for can body height..

b. Can ends will be manufactured slightly differently; however, CanReseal®’s ring ends and closures utilize the same shell & conversion presses and manufacturing processes making ends today for traditional non-resealable cans.

c. Fillers will be required to include a capper at the end of their line. CanReseal® is filled just like regular cans. However, our ring ends will likely be seamed on before, rather than after, the filling process.

d. Seamers can utilize their existing machinery to add CanReseal®’s ring ends to can bodies. Our development partner, Stolle Machinery, has developed a new seaming chuck that fits within today’s existing seaming machines. Additionally, modified track systems will be necessary for more efficient transportation of CanReseal® parts.

a. CanReseal® can satisfy any can size (diameters and volumes). Canovation is currently working on a 202-diameter beverage end development and a 300-diameter food can development. Simply put, our IP covers the addition of threads to inside of cans, not limited to any can size (volume or diameter).

a. Canovation does not intend to manufacturei. An interim step in our product development is to set up a low-volume pilot manufacturing line in partnership with a can maker to prove the manufacturability. Following the pilot line, Canovation will license the technology to can makers, rather than doing our own manufacturing.

The Future of Sustainable Packaging™

Become a CANovator, Lead the path to a greener future with a resealable packaging solution that’s 100% recyclable.

© 2025 Canovation. Canovation® and CanReseal® are registered trademarks of Canovation. Patented internationally, with other patents pending. All rights reserved. Contact Us / Privacy Policy