Governments worldwide are increasingly focusing on strategies to boost recycling rates and reduce waste, driven by the urgent need to address environmental concerns and promote sustainability. One of the popular approaches gaining momentum in this endeavor is the implementation of Deposit Return Systems (DRS). The concept of DRS dates back to the Canadian government’s pioneering efforts in 1970. Since then, many countries have recognized the value of this approach in combatting the issue of wrongly discarded plastic, glass, and aluminum drink packages. Among these nations, Germany has emerged as a trailblazer, achieving remarkable success with return rates of up to 98% for eligible drink containers.

In a DRS, businesses, typically retailers, proactively participate by raising the price of recyclable beverage containers by a few cents, which is then refunded to customers when they return the empty containers. This slight increase in cost, usually ranging from 10 to 20 cents, serves as a powerful incentive for people to bring back their empty containers, thereby not only promoting recycling but also significantly minimizing litter in public spaces. The benefits of DRS are manifold and far-reaching. They include boosting the collection rates of recyclables, streamlining sorting processes, and ultimately contributing to a cleaner environment. Moreover, it’s widely acknowledged that DRS initiatives can help conserve precious raw materials, reduce energy consumption, and cut down on CO2 emissions.

Yet, despite the evident advantages, opinions on DRS remain divided. Some concerns revolve around the added costs and operational complexities faced by store owners who are responsible for managing DRS. The funding of large-scale DRS operations becomes a contentious issue, with questions arising about who should bear the financial burden—store owners, extended producer responsibility laws, taxpayers, or the utilization of savings generated from unreturned materials.

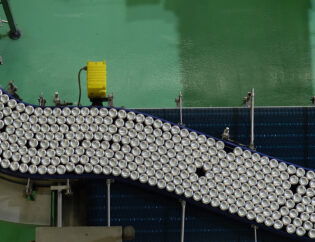

While the effectiveness of DRS in enhancing the sorting and recycling of materials is indisputable, it’s crucial to acknowledge that certain substances, such as glass and plastic, have limited recyclability due to quality degradation after multiple recycling cycles. This poses a significant challenge in achieving the sustainability goals set by governments and organizations worldwide. In stark contrast, aluminum stands out as a remarkable exception in the realm of recyclable materials. Aluminum can be recycled infinitely without compromising its quality, making it a shining beacon of sustainability. Therefore, for governments and organizations genuinely committed to establishing a truly circular economy, prioritizing aluminum recycling is not just advantageous but paramount.

The benefits of focusing on aluminum are profound. With existing infrastructure and minimal additional investment required, aluminum emerges as the key to realizing a genuine circular economy. By placing a spotlight on aluminum, we can effectively reduce waste, promote the sustainable use of resources, and significantly lower our environmental footprint. As we collectively embrace The Future of Sustainable Packaging™, we unlock the tremendous potential of aluminum to lead us toward a sustainable and circular future—one where environmental harmony and economic prosperity coexist.