Recycling has long been hailed as a solution to our growing environmental concerns, a powerful tool to reduce pollution and lessen our carbon footprint. However, the complexity of recycling, especially plastic, has made us pause to reconsider.

When we think of recycling, an image that often comes to mind is the green looping arrows, the universal symbol for recyclability. Alongside this emblem, there is a number system, ranging from 1-7, that classifies the plastic resin content of the item. For instance, the number “1” signifies PET, a material frequently used for plastic bottles. However, this number system is not a definitive guide to whether an item can or will be recycled. Recycling processes differ significantly based on geographical location, individual recycling facilities, and the services they provide. It becomes imperative for us, as responsible citizens, to understand what materials our local recycling centers accept.

Indeed, the concept of recycling is much more nuanced than it appears. Unfortunately, despite our best efforts, a significant portion of the plastic we’ve been ‘recycling’ may have ended up in landfills. The economic aspects of plastic recycling are also challenging. It’s more expensive to recycle plastic than to manufacture virgin plastic. This cost discrepancy is a major barrier for companies aiming to increase their usage of recycled content. Furthermore, plastic has a ‘shelf life’; regardless of its resin type, it can only be recycled a limited number of times before it loses its material value and becomes unrecyclable.

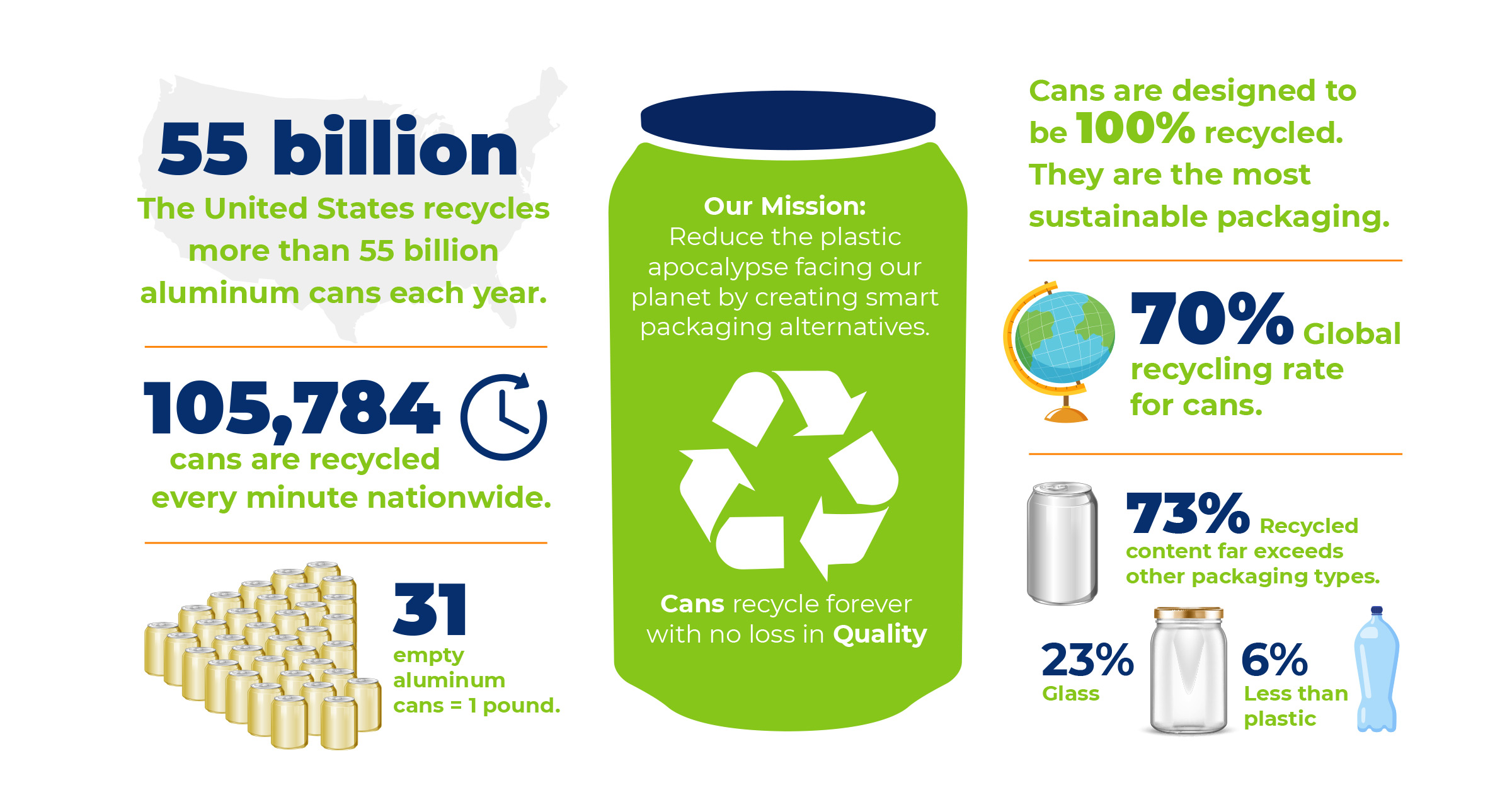

Enter aluminum, a material that presents a more sustainable alternative. Recycling aluminum is both cost-effective and environmentally friendly. Unlike plastic, aluminum can be recycled infinitely without losing its material value. The cost of recycled aluminum is comparable to plastic, making it a viable option for businesses. Importantly, using recycled aluminum instead of virgin aluminum saves significant amounts of water and energy. Compared to plastic, recycling aluminum provides much more substantial environmental benefits.

At Canovation, we believe in the potential of aluminum as a key player in sustainable packaging. We’ve developed CanReseal®, an all-metal, fully resealable aluminum can, that harnesses the inherent recyclability of aluminum. It’s our hope that this innovative solution will help beverage brands worldwide transition towards more sustainable packaging options, without compromising on quality or cost-effectiveness.

By making informed choices about the materials we use and recycle, we can contribute to a sustainable future. It’s not about demonizing plastic, but rather acknowledging the limitations of current recycling systems and exploring alternatives that can make a real difference. With its infinite recyclability and cost-effectiveness, aluminum emerges as a promising candidate in our quest for The Future of Sustainable Packaging™. Our innovative CanReseal® technology is a testament to this vision, paving the way for a more sustainable, circular economy in the beverage industry.